POF vs PVC

There are many types of shrink film. In this article, we will talk about two popular packaging materials: POF and PVC shrink film. Both are unique, with differences in clarity, durability, and performance. Let’s explore why POF is often a better choice for packaging than PVC.

Table Of Contents

POF Shrink Film

POF shrink film has become a smart choice for packaging consumer goods due to its superior characteristics and versatility. Made of polyethylene and polypropylene, POF offers excellent clarity, durability, and shrinkage properties.

Advantages of POF Shrink Film

Clarity

POF shrink film is known for its crystal-clear finish, enhancing the appearance of products. This transparency allows customers to see the product clearly without opening the packaging, making it ideal for retail display.

Durability and Strength

Highly durable, POF offers strong resistance to tearing, protecting products during transportation and handling, reducing the risk of damage.

Safety and Non-Toxicity

POF is 100% recyclable and free from harmful chemicals, making it safe for food and other goods. It meets various safety standards, giving peace of mind to both manufacturers and consumers.

Versatility

POF shrink film suits a wide range of products, from small consumer items to larger industrial goods. It is compatible with manual, semi-automatic, and fully automatic packaging machines.

In summary, POF shrink film enhances product display, ensures durability, and provides a safer, environmentally friendly solution, making it a leading packaging material across industries.

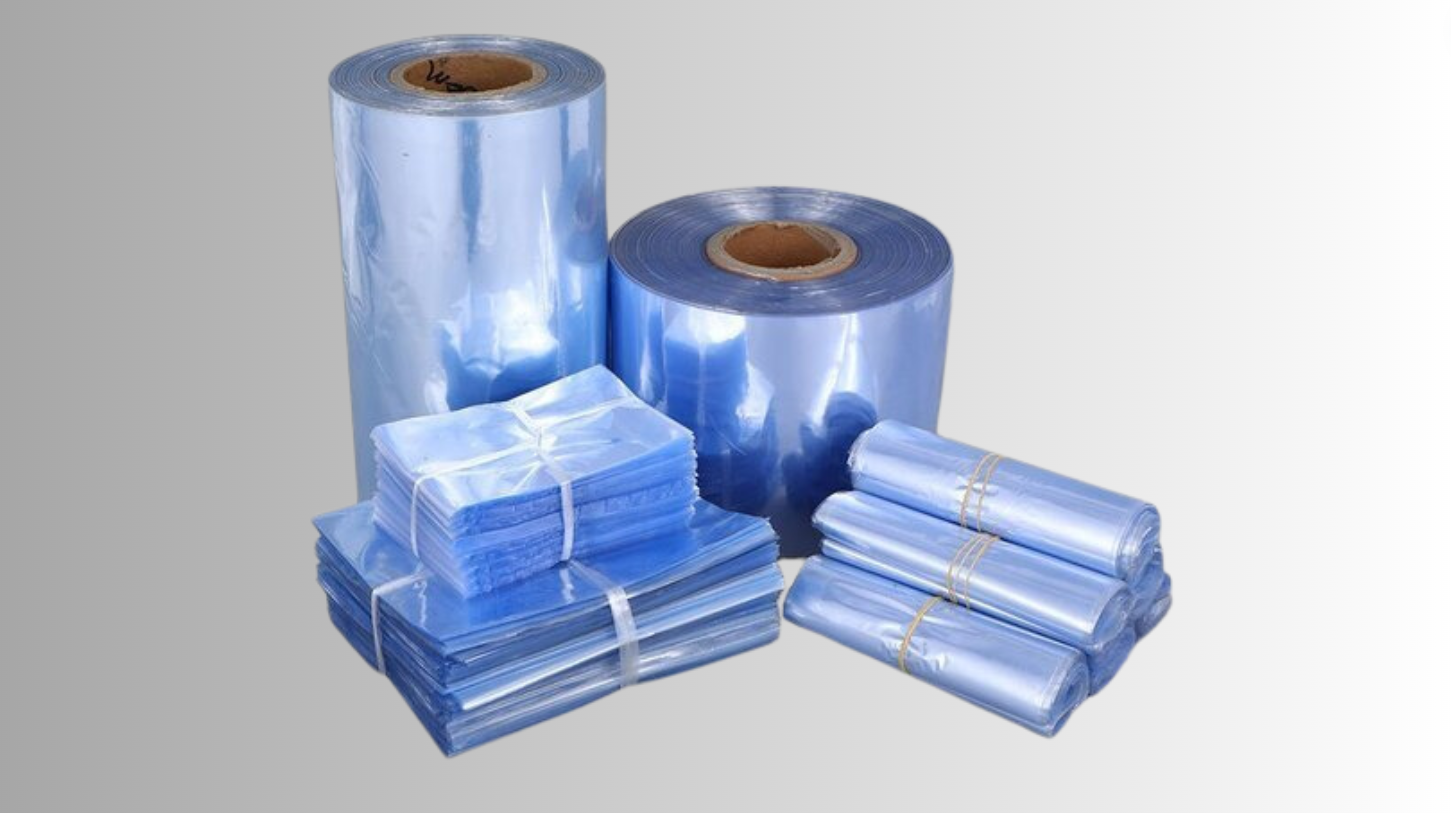

PVC Shrink Film

Polyvinyl chloride (PVC) shrink film has been widely used in packaging for many years. Known for its strength and durability, PVC has several advantages but also notable limitations.

Characteristics of PVC Shrink Film

Clarity and Gloss

PVC provides decent clarity and a glossy finish, giving products an appealing and professional look. This is important for retail packaging, where visual appeal can influence buying decisions.

Cost-Effectiveness

PVC is generally more affordable, making it suitable for businesses with high-volume packaging needs.

Shrink Ratio

PVC has a high shrink ratio, conforming tightly to products of various shapes and sizes. This is useful for packaging irregularly shaped items.

Durability

PVC is strong and tear-resistant, protecting products during transport and reducing losses and returns.

Limitations of PVC Shrink Film

Environmental Concerns

PVC production and disposal release harmful chemicals, including dioxins. Additionally, PVC is not recyclable, making it less environmentally friendly.

In conclusion, while PVC offers cost-effectiveness and durability, it poses environmental and chemical risks. Businesses looking for sustainable, versatile packaging may prefer POF shrink film.

Why Choose POF

1. Environmental Impact

POF is More Eco-Friendly: 100% recyclable and free from harmful gases, POF is a safer option for the environment. Waste can be reused easily.

PVC Has Environmental Concerns: PVC production emits harmful gases, making it less preferable environmentally.

2. Safety

POF is Non-Toxic: Safe for food packaging and other consumer products.

PVC Can Be Hazardous: Contains chlorine and can produce harmful chemicals during production, making it less safe than POF.

3. Versatility and Performance

POF Offers Greater Flexibility: Suitable for a wide range of temperatures and conditions, making it highly versatile.

PVC is More Inflexible: Limited flexibility, mainly usable at lower temperatures.

4. Cost-Effectiveness

POF is Cost-Effective: Durable and efficient, saving money and time over the long term.

PVC Can Be Costly in the Long Run: While upfront costs are lower, potential product damage and replacements can increase overall expenses.